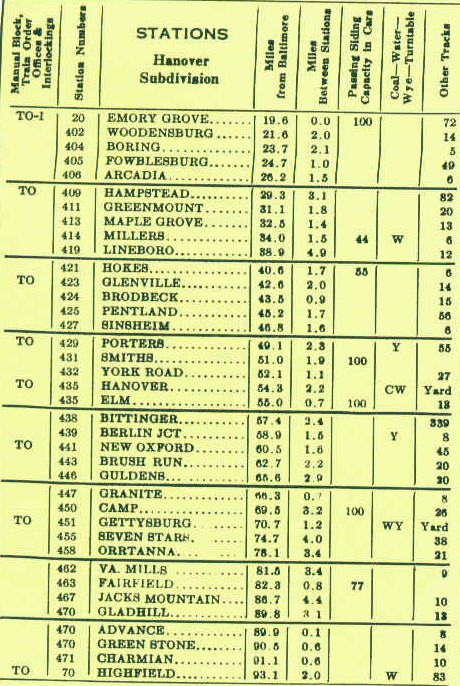

D778 (MON-FRI)

Station Arrival Departure Additional Information . . . . UPDATED 6/7/02

. . . . HANOVER PA ---- 2359 (ORIGIN)

YORK ROAD PA 0010 0020 1 mile approx

PORTERS PA 0035 0055 3 miles approx

LINEBORO MD ---- 0115 10 miles approx

HAMPSTEAD MD ---- 0145 10 miles approx

WOODENSBURG MD 0200 0210 7 miles approx

EMORY GROVE MD 0220 0230 2 miles approx

OWINGS MILLS MD 0245 0255 5 miles approx

LEHIGH YD MD 0335 0350 17 miles approx

ARLINGTON MD 0400 0410 1 mile approx

WALBROOK MD 0420 0430 1 mile approx

ARLINGTON MD ---- 0440 1 mile approx

LEHIGH YD MD ---- 0500 1 mile approx

OWINGS MILLS MD ---- 0545 17 miles approx

EMORY GROVE MD 0600 0610 5 miles approx

PORTERS PA ---- ---- 29 miles approx

BITTINGER PA ---- 0700 8 miles approx

NEW OXFORD PA 0745 0800 5 miles approx

GETTYSBURG PA 0830 0840 10 miles approx

ORRTANNA PA 0900 0915 7 miles approx

GLADHILL PA ---- ---- 11 miles approx

HANOVER PA 1030 ---- 36 miles approx

Comments: Hanover East

Assignment subject to change

Mixed Freight

Times shown are examples

D778

Baltimore Division Hanover East Times updated 6/7/02

INVESTIGATIONS OF RAILROAD ACCIDENTS 1911 - 1966

File Number 326

Railroad WESTERN MARYLAND RAILWAY

Date 01/07/1916

Location YORK ROAD, PA.

Accident Type D.

INTERSTATE COMMERCE COMMISSION.

REPORT OF THE CHIEF OF THE DIVISION OF SAFETY COVERING THE INVESTIGATION OF AN ACCIDENT WHICH OCCURRED ON THE WESTERN MARYLAND RAILWAY NEAR YORK ROAD, PA., ON JANUARY 7, 1916,

JUNE 19, 1916.

To the Commission:

On January 7, 1916, there was a derailment of a passenger train on the Western Maryland Railway near York Road, Pa., which resulted in the injury of 1 employee and 2 passengers. After investigation as to the nature and cause of this accident, I beg to submit the following report:

Westbound passenger train No. 7 consisted of 2 express cars, 1 combination car, 1 coach, and 2 sleeping cars, hauled by locomotive 201, and was in charge of Conductor Fauver and Engineman Gutshall. It was on route from Baltimore, Md., to Pittsburgh, Pa., when it was derailed near York road at 10.47 p. m. while traveling at a speed estimated to have been about 40 miles an hour. The entire train was derailed, with the exception of the locomotive and the rear truck of the rear sleeping car, but none of the equipment was seriously damaged, while the track was torn up for a distance of about 350 feet.

This part of the Western Maryland Railway is a single-track line. No block-signal system is in use, trains being operated by time-table and train orders. The accident occurred on tangent track at a point nearly 300 feet beyond the western end of a curve of 1 degree to the right, this curve being about 1,300 feet in length. The track is laid with 90-pound rails, 33 feet in length, single spiked to about 18 oak ties under each rail, ballasted with stone. No tie plates or rail braces were in use at the point of accident. The weather was clear.

An examination of the track showed that the derailment was due to a broken rail located on the north side of the track. This rail, which was a 90-pound rail, 33 feet in length, manufactured by the Maryland Steel Co., was rolled in December, 1905, and was originally laid in tangent main track in 1906. In September, 1915, it was removed and on account of showing little wear was shipped to Hanover, Pa., for use as a second-hand rail, and about December 20, 1915, it was placed in the track at the point where it broke on the day of the accident.

A portion of the receiving end of the rail about 11 feet in length was broken into many pieces, of which 56 were recovered. There was an old split extending nearly through the head of the rail, and the head was split loose from the web at the receiving end. The last fracture did not show any evidence of a split. Several small pieces of the broken head ;]so showed evidence of a split, this split being near the outside of the head. At a point about 3 feet 6 inches beyond the break the rail was cut in two, and the metal at this point appeared to be sound.

Locomotive 201 is a Pacific type locomotive, with a weight of 156,000, pounds on the driving wheels. The engineman in charge stated that he had not noticed anything wrong with the track as the locomotive passed over it, while nothing wrong was noticed when the last train previous to train No. 7 passed over the track. The preceding train was an eastbound freight train, which passed at about 9.3.5 p. m.

The examination of this rail for the purpose of determining the reason for its failure was conducted by Mr. James E. Howard, engineer-physicist, tests being made at Sparrows Point, Md., in conjunction with representatives of the Western Maryland Railway and the Maryland Steel Co., the manufacturers of this rail. The report covering the results of this investigation is as follows:

ACCIDENT NEAR YORK ROAD, PA., JANUARY 7, 1916.

REPORT OF ENGINEER-PHYSICIST.

The derailment of train No. 7 was caused by the fracture of a rail of 90 pounds weight, A. S. C. E. section, rolled by the Maryland Steel Co. in December, 1905. It was an "A" rail, as regard its ingot position, from heat No. 15694. The receiving end broke into a large number of fragments, of which 56 were recovered. The primary cause of failure was the presence of a split head, which had reached an advanced stage of development prior to its complete fracture under this train. Secondary lines of rupture were developed at the time of derailment, the latter separating the metal of the web and the base at a considerable number of places. Short pieces of the head, web, and base were broken off in succession by the wheels of the train, after the initial break was made by the forward part of the train, and presumably by the engine. Figure No. 1 is a general view of the fractured portion of the rail, taken from the gauge side. The fragments, on a less reduced scale, are also shown by the group of figures in illustration No. 2. Such of the fragments as admitted of being assembled in their relative positions are shown in these two illustrations.

The fracture of the rail occurred at its receiving end. The splice bars held the fragments at the extreme end in place, beyond which the fracture of the rail was complete. An opening was here made in the track, through which the derailed portion of the train passed. The section fractured was 11 feet long, of which length 8 feet showed the presence of a steam in the head. The shape of the fragments, in cross section, indicated that the origin of the split was in the upper part of the head, a short distance below the running surface. Individual fragments indicated that the split had been a progressive one, extending downward toward the web, and traveling lengthwise the rail from some definite although unidentified starting point. The recovered fragments wore insufficient to admit of recognition of the incipient place of rupture. A polished and etched cross section of the rail displayed markings characteristic of seamy steel; that is, acicular lines of structural unsoundness when viewed on end. Such seaminess is recognized as a common cause, leading to incipient separation of the metal, and eventually resulting in split heads and certain base fractures. These acicular lines are disposed parallel to the length of the rail. Some have considerable length, while others are short but associated with each other in such close proximity as to appear as continuous streaks, which at times are several feet in length. Their presence does not impair the ductility of steel, when strained in the direction of their length, but against deformations in a crosswise direction they have a decided influence in lowering the ductility of the steel. By reason of structural weakness and loss in ductility crosswise such streaks, opportunity is afforded for the starting of longitudinal fractures when lateral flow of the head of the rail occurs under the action of wheel pressures. Fractures of this kind have been found in an incipient stage in planing away the metal of the heads of rails, at a period of development much earlier than would admit of detection from surface indications. This evidence, acquired from the metal of the interior of the rail, confirms the conclusion that streaks of structurally weak steel are contributory causes to split heads and certain base fractures. The zone in which these streaks are present is located a short distance below the surface and parallel to the periphery of the rail. Streaks are found in the head, web, and base. Their symmetrical arrangement suggests a common origin which is attributed to ingot conditions, an inference which is supported by the results of the examinations of ingots and derivative shapes. Small blowholes in the ingot, with or without the presence of slag inclusions, suggest themselves as primarily responsible for the structural state witnessed in this rail. Interior seams, as well as surface defects, are of more serious import in hard steels than in mild grades of metal. Steel enriched in carbon and other elements--that is, segregated metal--is not held directly responsible for the formation of longitudinal seams, the origins of which are traceable to the presence of lines of structural weakness; although structural weakness, whether in acicular lines or planes of appreciable width, associated with hard steel, is regarded as an unfavorable combination. Minor defects in structure which are negligible in soft steel become a menace in hard steel. The conditions of service have much to do in defining what constitutes a serious defect in the metal, the need of structural soundness increasing as the stresses in the rails increase in magnitude and in the number of times the loads are repeated. The relations between structural defects and the grade of steel increase in importance as harder steels are used. The period in the process of steel making during which streaks have their origin, being confined to the ingot, as it is supposed, their elimination, partial or complete, is a metallurgical problem. Whatever difficulties interpose, streaks of this kind should not find their way into finished rails in greater degree than the state of the art renders unavoidable. Specific information on the condition of the steel before it is rolled, and in the early stages of rolling, before these acicular lines are developed by the reductions of the rail mill, constitutes information which is demanded. A physical state is displayed by the metal in the finished rail which is recognized as a common cause in many failures. Concerning the detection of rails in the track in which split heads are in process of development, they admit of recognition but at a late period. A general increase in the width of the head is one of the indications of a split head. The width of opening of an interior seam is closely represented by the gain in width of the head. The depth of the seam is many times its width. The head may be far advanced toward separation when its increase in width is first noticed. The formation of a fin along the edge of the head, from the lateral flow of the metal at the immediate surface, will not be mistaken for evidence of a split head, the general width of the head remaining unchanged. Other indications of split-head fractures consist of a slight depression along the middle of the top of the head, or the presence of a dark streak at that place, also local sags in the head, as seen from the side of the rail. Figure No. 3 shows the appearance of the top of the head of the present rail at a place just beyond the splice plates, at the receiving end. The recovered fragments from this part of the rail included both sides of the head. This permitted the placing of the fragments together and photographing them in approximately the relative positions they occupied before rupture was complete. There was a dark streak along the middle of the running surface about 0.60 inch in width. The general increase in the width of the head was 0.13 inch. Unruptured metal, about 1/16 inch in depth, between the running surface and the seam appeared to have existed prior to the time of derailment. Evidence was to the effect that surface indications of a split head were visible preceding the time of derailment. link to image FIG. No. 3-- View of head of fractured rail, showing dark streak along the middle of the running surface. Two features are brought into prominence in considering the primary cause of the derailment and the circumstances attending it; first, the need of eliminating interior structural defects in the steel, and, second, employing close scrutiny in detecting early indications of defective rails in the track. In the investigation of rail failures, it is essential to inquire into conditions associated with those which have led to specific failures. During the present examination supplementary data were acquired upon the state of internal strains and stresses which affect rails and which must be taken into consideration in judging of the total stresses which rails are being called upon to endure while in the track. These initial strains, markedly pronounced in steel in the form of rails tinder current methods of fabrication, are to all appearances just as real its the direct strains which attend the passage of a locomotive over the rails. The total stress in the steel is the sum of these strains which include the cooling strains of fabrication, the cold rolling strains in the head resulting from successive wheel pressures on the running surface, and the direct bending loads which are present when the locomotive and train are supported by the rail. The magnitude of the stress is the algebraic sum of these several components, since the direct loads of the equipment cause reversed stresses of tension and compression, according to the position of the wheels, with reference to any given place on the rail. The state of the initial strains in the present rail was ascertained, in a section taken from the receiving end, just beyond the last fracture made at the time of the derailment, also in a section from the leaving end of the rail, each section being examined in the condition it was left by the derailment. A duplicate section was taken from the receiving end, which was annealed before its examination. In addition, pieces of new rails were examined for the purpose of ascertaining the primitive strains acquired during fabrication, those resulting from accelerated and from retarded rates of cooling, the residual strains after annealing, also measuring the modified strains in sections which had been gagged. A few observations were made, illustrating the manner in which exposure of the base of the rail to heat affects the head, the, expansion of the base by rapid heating, momentarily causing contraction of the upper elements of the head. link to image FIGURE No. 4--Cross section of 90-pound rail. Stresses corresponding to the initial strains in section of rail near its fractured receiving end. Referring to the rail which caused the present, derailment, the stresses corresponding to the strains which were present in the rail near its fractured receiving end are shown on figure No. 4. There was a maximum stress of compression of 11,100 pounds per square inch at the top of the head. The sides of the head and the web were each in a state of compression. It will be noticed, however, that the edges of the flanges were in a state of tension, an unusual circumstance, which requires explanation, since the flanges are also expected to be in compression when normal cooling strains of fabrication alone are present. At the time of derailment the receiving end of this rail was subjected to bending stresses of unusual degree. Pieces were broken off in succession by the hammering of the wheels of the train after an opening had been made in the track. In consequence of this the overhanging end was bent downward, overstraining the rail, and resulting in the reversal of the strains in the flanges from a primitive state of compression to a final state of tension. It has been previously shown that in bars similarly bent the final initial strains in the outside fibers are the reverse of those present while the bending load is acting; that is, strains of tension are left on the concave side of the bent bar and those of compression on the convex side. The understrained metal, lying near the neutral axis, remains unchanged; that is, with compression on the concave side and tension on the conyex side of the bend. This modified state of initial strains in bent bars is again referred to, since the apparent anomaly of strains of tension being on the inside of a bent bar, and compression on the outside, is a matter at times misinterpreted. link to image FIGURE No. 5.--Cross section of 90-pound rail. Stresses corresponding to the initial strains in section of rail near its leaving end. The final state of strain existing in this part of the length of the rail is taken to be a reliable record of the vicissitudes through which it passed at the time of the derailment. The tensile stresses in the flanges are consistent with the conditions which attended its fracture. Figure No. 5 shows the stresses which were present in the section taken from the leaving end of the rail. In this section the initial strains were more nearly normal to rails which have been exposed only to usual track conditions. It is believed, however, that this portion of the rail was subjected to an unusual load at the time of derailment, but of lesser degree than the receiving end. Records of initial strains furnish reliable evidence of a permanent character upon some of the conditions attending the previous treatment of the steel. The complex conditions which affect rails frequently render their interpretation difficult, and, with present knowledge, at times impracticable. The third section from the fractured rail was annealed. The results appear on figure No. 6. The initial strains throughout were of moderate degree, showing a decided reduction below those witnessed in the other two sections and below those generally in rails of similar dimensions and weight. The effect of annealing is to efface initial strains, the magnitude of the primitive strains and the annealing temperatures being factors which influence the results. Observations were continued upon a series of seven sections of 85-pound rails, those having rather thin flanges, of the type known as the Dudley section. New rails were used in which the strains were measured due to cooling under normal conditions, those resulting from an accelerated rate of cooling, and those from a retarded rate of cooling, also strains which remained in the rail after annealing and the strains as they were modified by the operation of gagging. link to image FIGURE No. 6.-Cross section of 90-pound rail. Stresses corresponding to initial strains in section of rail, near its receiving end, after annealing. The section which represented the normal rate of cooling was taken from the end of a rail which cooled in the usual manner on the hot bed of the rail mill. The section of accelerated rate of cooling was cooled rapidly by a blast of air directed upon it by a hose, the air being applied immediately after the section came from the hot saw, and continued until the section was cool enough to handle. The section of retarded rate of cooling was buried in dry ashes, in company with two other sections, each taken immediately after hot sawing. The two additional sections were placed in the ashes in order that the increased volume of metal might aid in accomplishing a slow rate of cooling. The gagged sections were taken from a rail which cooled normally on the hot bed. Diagrams are inserted showing the stresses which corresponded to the initial strains observed. Figures Nos. 7 to 13, inclusive, on diagram A, show the final results on the 85-pound rails. Figures 7, 8, and 9, lettered "a" to "d," on diagram B, show the strains in three of the sections at each of the intermediate stages of the examination. Under the normal rate of cooling, as shown by figure No. 7, the stresses of compression in the flanges were found to be 16,800 and 18,300 pounds per square inch, respectively, with a tensile stress of 4,800 pounds in the elements along the middle of the width of the base. Lower stresses prevailed in the head, the maximum compression there being 6,900 pounds per square inch. The thinner metal of the flanges permitting a more rapid rate of cooling, accounts for the difference in the initial strains in the head and the base. The total range in stresses in the base, those of tension plus those of compression, were 23,100 pounds per square inch. Under the conditions of accelerated cooling, as shown by figure No. 8, the initial strains were much increased, particularly in the thinner parts of the web and the base. The maximum compression in the flanges rose to 33,300 pounds per square inch, with tension along the middle of the base of 19,200 pounds per square inch. The total range in stresses in the base was therefore 52,500 pounds per square inch. The metal at the middle of the web showed a compressive stress of 11,400 pounds. Less pronounced effects were found in the metal of the head, each gauged length of which, however, showed higher results than in the normally cooled section. The section of retarded rate of cooling, figure No. 9, showed moderate initial stresses along each of the elements examined, which did not materially differ in magnitude from those of the annealed section, figure No. 10. The results upon this section furnish data concerning the period in the fabrication of the rail when the initial strains are acquired. It appears that initial strains are chiefly acquired during the period of cooling, succeeding the last pass in the rail mill. The reductions in the rolls, occurring at a time when the metal is plastic, do not appear accountable for the final strains which are in the rails. The difference in the rate of cooling of the thick and thin sections of the rail chiefly influences the results. Sections having thin flanges may be expected to display greater initial strains than those with heavier bases. Steel is susceptible of-acquiring initial strains by rapid cooling from higher temperatures, which slow cooling ameliorates. A state of complete repose, in which initial strains are entirely absent, is not practical to reach in rolled and forged shapes. The shape of a steel rail is one that readily acquires internal strains, which weight and dimensions of section modify. The effects of gagging are shown by figures Nos. 11, 12, and 13. It has been remarked that initial strains of tension or of compression may be introduced at will en one side or the other of a bar, according to the direction of the bending load. It follows that a modification of the initial strains in a rail may be effected in a similar manner by cold bending. The strains introduced during cooling admit of being disturbed and even reversed by gagging. The reversal of the strains in the top of the head from a state of compression to that of tension is shown in the results entered on the diagram, figure No. 11. It also appears that a state of reduced strain was effected in the metal of the base. Stresses of 1,200 pounds tension and compression, respectively, were displayed by the flanges of the section that was gagged in two directions, figure No. 13, against a maximum compression of 18,300 pounds per square inch in the section normally cooled. The initial strains pertaining to the sides of the head of the rail represent the mean effect on strips of the full depth of the sides. The influence of position of the metal with reference to its distance from the neutral axis is a factor to be considered in judging of the effects of gagging. The results on these strips, the sides of which were at varying distances from the neutral axis, will therefore be taken as representing mean stresses. The opposite edges of the strips were doubtless affected by strains of different degrees of intensity. Figure 7 Stresses corresponding to initial strains in new rails after different conditions of cooling, annealing, and gagging. Figure 8 Initial strains in new rails. Strains released at successive stages in cutting up sections during examination for initial strains. Figure 9 Permanent sets in heads and bases of new rails, resulting from gagging. Also strains transmitted to head of rail by rapid heating of base. These gagged sections were found to have strains present of diminished magnitude over those in the section of the rail which cooled normally. The operation of gagging, in so far as it related to these sections, was therefore an ameliorating process rather than one which increased the intensity of the strains in the surface metal of the rail. The rate of change in the intensity of the initial strains, in passing from the periphery of the rail toward the center of the section, probably differs according to the volume of the rail and its rate of cooling, differing also in rails which are gagged and in the cold-rolled metal of the head. Each change in cross-section dimensions, occasioned by detaching individual strips, was attended with a rearrangement of the initial strains in the remaining portions of the rail. The removal of a strip of metal from one portion disturbs the state of equilibrium previously existing and causes measurable changes in the adjacent parts of the rail, and in many cases changes that are measurable in each of the remaining parts of the section. The rails were examined at each of the intermediate stages, during which the several strips were being detached. The results obtained on three of the sections are introduced in this report, on diagram B. Figures 7a-d show the strains released when the section, which was cooled normally, was cut up for examination. The shaded parts indicate the cross section of the rail at successive stages, while the figures affixed show the total strains which were released at each of those stages. Referring to these results, it was found that when the side strips were detached from the head of the rail they expanded 0.0015 inch and 0.0017 inch, respectively. The removal of metal in a state of compression permitted the strains in the remaining part of the cross section to readjust themselves, in consequence of which the metal along the top of the head contracted, the strain there displayed being 0.0011 inch. All measurements refer to original gauged lengths of 10 inches each. When the strips from the flanges were detached they expanded 0.0056 inch and 0.0061 inch, respectively. The metal along the middle of the base at this stage showed a contraction of 0.0010 inch. Upon a further reduction of the width of the base to 1 inch the total contraction increased to 0.0031 inch. The maximum observed contraction at the middle of the base was displayed before the thin strip 1 inch wide was detached from the lower face. There was a recovery of 0.0015 inch, leaving a final contraction of 0.0016 inch in the detached strip. This result indicated that a higher state of tension existed in the interior portion of the rail at the junction of the web and base than pertained to the surface metal. Indications of this kind enable the presence of strains in other parts of the rail to be recognized, of greater intensity than those in the particular parts included in the measured strips. In the metal of the head a reversed movement occurred which reduced the first measured change of minus 0.0011 inch to minus 0.0009 inch and then to minus 0.0005 inch. Finally, the strip from the head expanded to 0.0023 inch above its primitive length. Changes in the web also occurred during these reductions in cross-section dimensions, which are shown on the diagram. In the section of accelerated rate of cooling, the initial strains were greater, and their changes during readjustment were more pronounced than in the section of normal rate of cooling. At the top of the head the successive strains were contractions of 0.0016 inch, 0.0010 inch, and 0.0008 inch, respectively, with a final movement of expansion of 0.0024 inch when the strip was detached, thus displaying a total range in plus and minus directions of 0.0040 inch. This range is equivalent to a stress of 12,000 pounds per square inch. In the thinner parts of the base, where the initial strains greatly exceeded those of the head, the successive changes were greater, and the total range in the stresses was also greater than in other parts of the cross section. In plus and minus directions the range in stresses in the base amounted to 52,500 pounds per square inch. The progressive and total strains displayed by the section of retarded rate of cooling were of moderate extent. The latter section furnished an example, illustrating common knowledge, that steel slowly cooled does not acquire high initial strains. Strains may be eliminated, or at least partially, by annealing, effacing in part these which had been acquired, and also, by slow cooling from the temperature of rolling, they may in part be prevented from forming. While the steel is in its plastic state, at rolling temperatures, initial strains can hardly exist of substantial amount. The period when they are acquired is at lower temperature, after the metal has reached a state of partial rigidity. The capacity for retaining initial strains is apparently controlled by the elastic limit of the steel. If the metal is allowed to cool after any of the passes in the blooming or rail mill it would then acquire initial strains. These earlier shapes have displayed initial strains when cold, but of lesser degree than witnessed in the finished rails. A distinction must be made between the amount of extension or compression which may be given the rail by the process of gagging, and the initial strains which result therefrom. The capacity for initial strains is necessarily limited to the elastic limit of the metal that is, the initial strains in an ordinary rail can hardly be greater than represented by two-thousandths of its length, the strain corresponding to an assumed elastic limit of 60,000 pounds per square inch, whereas the total extension or compression from gagging may be any reasonable amount-several times the amount of the initial strain which results therefrom. In respect to the amount of extension or compression given the rail, gagging is not the same as peining the surface, nor the same as the cold rolling streets of wheel pressures; each have their own characteristics. It is necessary to refer to these matters at length in order that at least some of the governing principles may be made clear. They do not admit of brief mention, and yet a discussion covering only the main features might seem prolix. It is believed, however, that the importance of the subject is such as to justify presenting the details at considerable length. The normal stresses which affect rails--that is, the direct bending stresses from wheel loads--cause unit stresses considerably higher than engineering practice prescribes for use in permanent structures, and to these direct stresses the initial strains must be added to show the total strains and stresses in the rails. Initial strains have not generally been given due consideration. They have not even been measure in many instances. The present determinations and those of earlier reports show the initial strains to be of magnitude approaching or even exceeding at times the direct bending stresses of the train loads. The susceptibility of steel to receive initial strains, long known to be a fact, is clearly shown in the present examination and those of earlier date. It has been shown by many tests that steels may be ruptured by repeated stresses, unaccompanied by the display of ductility, and that fewer repetitions are necessary to accomplish rupture in proportion as the loads are increased; furthermore, that the characteristics of initial strains are the same as those due to external loads. These considerations make it necessary to take into account the magnitude of the initial strains as having an influence upon the ability of the steel to endure repeated loads with safety. Internal strains from cooling at time of fabrication and those from cold rolling in the track are not negligible factors. Referring to the measurements which were made on pieces of rails when gagged, the results of which appear on diagram C: Rails of 100 pounds weight, A. R. A.-B section, were employed. Rail A, figures Nos. 14a-d, was first gagged on the, head, causing a permanent set of compression on the top of the head of 0.0081", with an attending set of extension on the base of 0.0041". The rail was reversed and gagged on the base. The permanent sets were accordingly reversed, the head now being extended and the base shortened. This was followed by regagging on the head. The amount of gagging was about the same as that normally given in the regular work of rail straightening. Repeated gagging is believed to be accomplished with less mechanical work than that required on the first occasion. This impression is held by those at the gagging press and is consistent with the known reduction in the elastic limits caused by overstraining the steel and consistent also with observations which have been made on the power required to drive shafting, rotated under overstraining loads. Progressive fractures are not started necessarily at this stage, the reduction in resistance to gagging being attributable to the lowering of the elastic limits of tension and compression and the slight attendant reduction in the value of the modulus of elasticity. The portion of the cross section of the rail near the neutral axis is not overstrained by gagging, hence it is the behavior of the fibers which are remote from the neutral axis that accounts for the reduction in the amount of bending force required in the case of repeated gagging. In both of the gagged rails, A and B, it will be noted that the permananet sets in the head were greater than those of the base. This result occurred regardless of whether the sets were of extension or compression. Differences in the physical properties of the thick and the thin sections of the rail, and in the primitive initial strains from cooling doubtless influence the relative display of sets in the head and the base. The measured extensions and compressions of the metal upon reversal of gagging operations furnishes evidence that the length of the rail over all does not undergo any decided change in length in consequence of gagging. Gagging beyond the gauged length, on each end, was done without causing measurable change within the gauged length. The longitudinal effects of gagging are, of course, greatest in the outside fibers of the rail. The interior fibers are strained in a lesser degree than those at the top of the head, or along the lower surface of the base. While any straining beyond the elastic limit of the steel may be considered as having a detrimental tendency, and if long continued would eventually end in rupture, nevertheless the overstraining of rails for the purpose of straightening them, by loads once applied, and of a magnitude causing permanent extension amounting to only one-tenth of 1 per cent, should not seriously affect a grade of steel which is suitable for rails. In a crosswise direction, the effect of the plunger of the gagging press, according to the testimony of those, in position to make frequent observations, does not cause material visible deformation. Rails are at times subjected to rapid heating by the slipping of wheels, resulting in "wheel burns," so-called. Momentarily a state of strain is set up which is modified as soon as the transmission of the heat wave has time to take place. There is a wide difference in the rate of transmission of such heat waves and the transmission of the strains which are caused by the sudden application of heat to the surface of the rail. The trends of wheels and brake shoes are affected in this manner more frequently and with greater severity than in the case of rails. The display of elastic extension or compression takes place with rapidly applied loads without noticeable lag, when the stresses do not exceed the elastic limit of the steel. Observations on this feature have been made with speeds of loading up to about one hundred and fiftieth of a second, and from zero load to a maximum tension or maximum compression of 40,000 pounds per square inch. The transmission of heat waves, on the other hand, is very sluggish, in a comparative sense. Heat suddenly applied to one surface of a rail will momentarily cause a reversed strain in the opposite face, before equalization of temperature occurs. Heating the base of the rail and extending the metal on that side will momentarily cause 1 a shortening of the rail along the top of the head and this will be maintained until the heat wave is transmitted and the temperature of the rail is approximately equalized, after which the top of the head will, of course, lengthen. The results entered on the diagram herewith show the contractile movements observed when a rail of 100 pounds A. R. A.-B section was placed upon a hot billet. The first observation showed a contraction of 0.0003 inch, the second a contraction of 0.0005 inch, and the third a contraction of 0.0006 inch, the rail remaining on the hot billet different intervals of time. Between each observation the rail was cooled. The maximum contraction mentioned corresponds to a stress of 1,800 pounds per square inch. When the heat wave reached the top of the rail an expansion necessarily took place. The final observation was made after the rail had rested on the hot billet for a. period of 15 minutes. The expansion at this time was 0.0125 inch, which increased to 0.0155 inch five minutes later, the rail in the meantime having been removed from the source of heat. During a portion of the time of these observations the metal at the running surface of the head was in a state of compression. According to the shape of the section, or the point of application of the heat, the adjacent parts c the rail might temporarily be put into either tension or compression. Rails, wheels, and brake shoes pass through thermal changes of this kind, which contribute their share in augmenting the direct strains of service. A general summary of the results of the measured strains which were found in the several sections is shown on Table No. 1: Table 1 TABLE No. 1.-Initial strains in steel rails. [Stresses, pounds per square inch, corresponding to measured strains. Compressive stresses in ordinary-faced type. Tensile stresses In heavy-faced type.] The individual strips on which the initial strains were measured were annealed, the results of which appear on Table No. 2. They were box annealed at an estimated temperature of 1,400 degree F. The temperature of the furnace was gradually raised and maintained at the maximum for an interval of 1 hour, after which it slowly cooled, the strips remaining in and cooling with the furnace. The general result of the annealing was a shortening of the strips. Table 2 TABLE NO. 2,--Strips annealed at 1,400 degree F. [Contractions on gauged lengths of 10 inches each.] Increase in ganged length. Certain of the strips were reannealed at an estimated temperature of 1,450 degree F. The strips were kept in the furnace for a period of 3 days, during which interval the maximum temperature was maintained for a period of about 3 hours each day. Each strip, when cooled, showed additional contraction in length. These strips were again annealed, for a third time, being kept in the furnace for a period of 6 days, raised to and maintained at an estimated temperature of 1,450 degree F. for a period of about 4 hours each day. The strips continued to contract in length, as shown by the measurements taken when they were cold. Table No. 3 shows the amount of the shortening of each strip on gauged lengths of 10 inches each, caused by each annealing, and the total amount resulting from the three annealings: Table 3 TABLE No. 3.-Contractions of strips on gauged lengths of 10 inches each, caused by each of 3 annealings, and total contractions resulting therefrom. Increase in gauged length. It is seen that repeated annealing of the strips resulted in successively shortening their lengths in amounts which eventually ranged from about one hundredth of an inch to four hundredths of an inch on gauged lengths of 10 inches each. Thus a very material change in this dimension was effected without evidence that the maximum amount had been reached. In order to further illustrate the physical changes to which steel is susceptible a few of the strips were subjected to other treatment for the purpose of reversing the contractible movement of annealing and causing an expansion in their lengths. These strips were heated to a temperature of approximately 1,000 degree F. and quenched in water. The expansions displayed by these strips are shown in the accompanying table, No. 4. Table 4 TABLE No. 4--Expansion of strips, on gauged lengths of 10 inches each, by quenching from a temperature of approximately 1,000 degree F. The above expansions correspond to stresses ranging front 2,100 to 5,400 pounds per square inch. The equivalent values in stresses which are brought about by such means; modifying the rate of cooling at the time of fabrication of the rail, influenced by the thinness of different parts of the rail section; by heating followed by slow or rapid cooling in the finished rail; or by the cold rolling effects of wheel pressures, emphasize how much should be taken under consideration in addition to the direct stresses of the wheel loads on the rails in the track. Bending tests were finally made on a number of the strips, on those which had been annealed only, and on others which were quenched after annealing. The thinner strips from the head and base were bent cold, through an angle of 180 degrees, and closed down without fracture. Strips front the edges of the flanges, having the full depth of the base at that place, were bent 180 degrees to a radius of curvature of three-fourths inch, also without fracture. The elongation of the metal on the tension side of the curved portions of the flange strips ranged front 12 to 17 per cent in the different rail sections, this extension not exhausting the amount which the steel was capable of displaying. The chemical composition of the rails examined and herein reported upon is shown on Table No. 5: Table 5 TABLE NO. 5.-- Chemical analyses of rails In conclusion, it appears that the cause of the failure of the rail, which resulted in the derailment of train No. 7, was a split head. This was induced by the presence of seamy, acicular metal which was located in a zone a short distance within the periphery of the rail. The seamy metal below the running surface of the head was exposed to lateral flow, the usual effect of wheel pressures. The absence of, or impairment of, ductility in the steel, crosswise these seamy lines, led to the formation of incipient cracks, it is believed, which gradually extended until a split head resulted. The presence of seaminess is a structural defect which has its origin in the ingot, the elimination of which is a metallurgical and mill question. The elimination of seamy steel, complete or partial, will effect an improvement in rails and remove the common cause of many rail failures. The presence of the split in the head of this rail, it is believed, admitted of detection prior to the derailment. The increase in width and the presence of a dark streak along the middle of the running surface were each the usual indications of a split head. SUMMARY. The result of this investigation shows that the failure of the rail which caused the derailment of train No. 7 was due to a split head. Rail failures of this kind are not of infrequent occurrence, since lateral flow of the metal of the head, the result of wheel pressure, leads to this type of fracture. The immediate cause of the disturbance of the metal of the head is therefore the wheel pressures, but back of this is the matter of structural soundness of the steel, which is the vital, feature in many instances and is the important one in the present rail. Sound steel will display a certain amount of ductility when tested by tension, and will display a greater amount when cold swaged drawn, or cold rolled-that is, when its own strength is not called upon to cause the extension. In rails of medium hardness fins form along the sides of the head, illustrating the primitive ductility of the steel, the metal which forms these fins coming chiefly from the top of the head. Seaminess of the steel detracts from this ability to flow in a lateral direction, hence when the rail contains seamy metal in the head there is a tendency, when strained laterally, to develop incipient cracks which ultimately extend and finally result in split heads. If the surface metal is softer than that of the interior of the head, then such a condition in conjunction with seaminess increases the tendency to form split heads. The real danger, it would appear, has to do with seaminess rather than segregation. The symmetrical arrangement of those marks which appear on the cross section of etched rails and represent seaminess place the responsibility for their presence on the state of the metal in the ingot. Investigation has shown that seaminess in the base has the same character as that which is found in the head, and certain base fractures are attributable to such seaminess. In the web, however, less trouble is experienced from this cause. An improvement in ingot conditions should effect an improvement in both the metal of the head and the base, and definite information should be acquired on the structural state of the metal in the ingot in a sufficient number of examinations to fully demonstrate the extent to which the causes seaminess prevail, as well as what remedial measures can be adopted to prevent their recurrence. It is important, as a mill question, to remove the causes of seaminess, while in reference to track maintenance it is necessary to exercise diligent scrutiny in the detection of rails which are failing, and which present evidence of the same by surface indications. This rail apparently displayed evidence of a split head on the running surface prior to its complete failure, in showing a general increase in width, and also in exhibiting a dark line along the middle of the head, the latter being a feature which is commonly recognized as the visible indication of a split head. It so chanced that this was a relaid rail, but that circumstance is believed to have no direct bearing upon its failure. Briefly summarized, it is a desideratum that the causes of seaminess be eliminated from the ingot or elsewhere, if not confined to ingot conditions, but until there is assurance of the elimination of the causes of seams, reliance must be placed on track inspection for the detection and removal of rails having split heads. Since the depth of the seam in the head of a rail is many times its width, the detection of a split head is confined to evidence which is furnished by the lesser dimension of the seam, and such inspection becomes, essentially, a rigorous matter. This report contains further data upon the state of initial strains which affect rails. Rails are exposed to repeated alternate stresses, and it has been shown by laboratory tests that an increase in the fiber stresses of steel exposed to repeated stresses lowers its limit of endurance, which diminishes very rapidly when the loads attain certain limits, that is, when the fiber stresses approach the elastic limit of the metal. It is further known that the direct bending stresses of rails in the track are-very high in comparison with the unit stresses which are deemed prudent to use in other engineering structures. The presence of initial strains from cooling during fabrication and those due to the cold rolling action of the wheels on the running surface of the head increase the total stresses of the rails when the wheels are in certain positions. Necessarily, these initial strains should be taken into consideration in judging of the strength and ability of the rails to endure the loads which are imposed upon them in the track. It does not appear, however, that such consideration has been given the subject. The present report also contains measurements on the initial strains in rails under normal conditions of cooling, when the rate of cooling was accelerated, when it was retarded, and strains present in annealed sections. The effects of gagging are also shown. The subject of gagging throughout the history of rail making has been a discursive theme, without attaining definite ends. In respect to the present results, the magnitudes of the initial strains in the gagged sections were found to be lower than those in the corresponding section which cooled normally. In the head, the normal condition of a state of compression was reversed and initial strains of tension were introduced. Laboratory tests of an early date showed such a reversal of strains would be expected as a result of gagging. The report invites attention to the distinction which should be made between the permanent sets of tension or compression which are given the rail by the process of gagging and the initial strains which result therefrom. A few observations were made on the transmission of stresses by heating one part of the rail, the head being shortened by rapidly heating the base. This temporary contraction of the metal of the head was, of course, lost when the temperature of the rail was equalized. The effects of sudden heating have a bearing upon the strains momentarily introduced in rails when "wheel-burns" occur, as well as influencing the strains brake shoes and the rims and plates of wheels. The transmission of strains occurs immediately, while a slower action attends the equalization of temperature.

Respectfully submitted.

H. W. BELNAP

Chief Division of Safety.

ADDITIONAL COPIES OF THIS PUBLICATION MAY BE PRODUCED FROM THE SUPERINTENDENT OF DOCUMENTS GOVERNMENT PRINTING OFFICE WASHINGTON, D.C. AT 10 CENTS PER COPY V WASHINGTON: GOVERNMENT PRINTING OFFICE: 1916